Tag: gas spring patent

forced mechanical locking gas spring

Patent No.:CN101487507 Date:2008-01-14

Google Patent: https://patents.google.com/patent/CN101487507A/en?oq=CN101487507

China Patent: http://epub.cnipa.gov.cn/

Abstract

This invention provides a type of forced mechanical locking gas spring, including a gas spring cylinder, a built-in piston inside the cylinder, a piston rod riveted to the piston, a guiding and sealing system, and a front connector attached to the piston rod, with a locking sleeve and a return spring attached to the front connector. The wrench bracket is welded onto the locking sleeve, and the strong locking wrench is installed on the wrench bracket. By adopting the two components of the wrench bracket and the strong locking wrench, it not only relies on the locking sleeve’s offset to support the lock but also has a strong locking wrench for forced locking, thereby doubling the safety factor during use. It is suitable for environments where malfunctions easily occur, such as facilities and equipment, and is also applicable in other fields such as sports equipment and treadmills.

Description

A Type of Forced Mechanical Locking Gas Spring

Technical Field The invention relates to a gas spring, specifically a type of forced mechanical locking gas spring.

Background Technology Gas springs are considered safety components abroad and have their own integrity requirements. In practical applications, there is an increasing focus on safety. In this context, using gas springs as mechanical locking devices has become more common. The current market’s locking devices rely solely on the offset of the locking sleeve to support the lock, which is unsuitable for environments prone to operational errors.

Summary of the Invention This invention provides a type of forced mechanical locking gas spring with double safety assurance.

To solve the above technical problems, the forced mechanical locking gas spring of this invention includes a gas spring cylinder, a built-in piston inside the cylinder, a piston rod riveted to the piston, a guiding and sealing system, and a front connector attached to the piston rod, with a locking sleeve and a return spring attached to the front connector. The wrench bracket is welded onto the locking sleeve, and the strong locking wrench is installed on the wrench bracket.

The strong locking wrench’s locking part is in the shape of an eccentric wheel and can be turned 180°.

The advantage of this structure is that it utilizes the two components of the wrench bracket and the strong locking wrench. It not only relies on the locking sleeve’s offset to support the lock but also has a strong locking wrench for forced locking, thus doubling the safety factor during use. It is suitable for environments where operational errors are likely, such as facilities and equipment, and is also applicable in other fields such as sports equipment and treadmills.

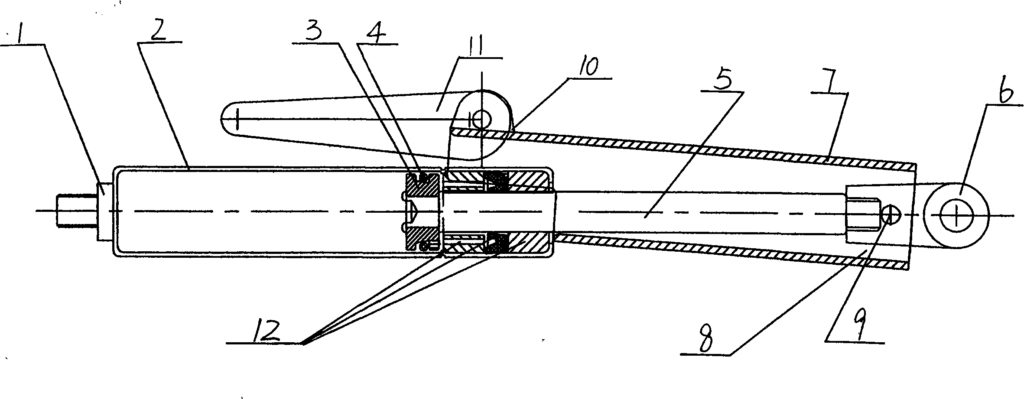

Description of the Drawings The figure is a schematic diagram of the structure of the invention.

Detailed Implementation As shown in the figure, the rear plug 1 and the cylinder 2 are welded into a sealed gas spring cylinder. The piston 3 and the O-ring 4 form a complete piston, with a guiding and sealing system 12 for guiding and sealing at this location. The piston is riveted to the piston rod 5. The front connector 6 is attached to the piston rod 5. The locking sleeve 7 and the return spring 8 are connected to the front connector 6 by the locking sleeve bolt 9. The wrench bracket 10 is welded onto the locking sleeve 7, and the strong locking wrench 11 is installed on the wrench bracket 10. The strong locking wrench 11’s locking part is shaped like an eccentric wheel and can be turned 180° to achieve the functions of strong locking and unlocking.

In operation, taking the maintenance of a large and heavy machine door as an example, the machine door needs to be opened and kept open for a long time during maintenance. At this time, the gas spring’s function is to open and support. The ordinary locking support component on the gas spring relies on the small force of the return spring 8 for the locking sleeve 7’s offset, achieving the purpose of support and locking, but it cannot prevent accidents. In this case, the wrench bracket 10 welded onto the locking sleeve 7 applies force to the strong locking wrench 11, which turns 180° like an eccentric wheel, initiating the strong lock function, thereby achieving dual mechanical locking and reducing safety risks.

Claims (2) – forced mechanical locking gas spring patent by LeiYan

- A Type of Forced Mechanical Locking Gas Spring, including a gas spring cylinder, a built-in piston inside the cylinder, a piston rod riveted to the piston, a guiding and sealing system, and a front connector attached to the piston rod with a locking sleeve and return spring attached to the front connector. It is characterized by: the wrench bracket being welded onto the locking sleeve, and the strong locking wrench being installed on the wrench bracket.

- According to claim 1, the strong locking wrench’s locking part is in the shape of an eccentric wheel and can be turned 180°.

Gas spring with variable force value and circulating and reversible rotation angle

Patent No.:CN101487482 Date:2008-01-14

Google Patent: https://patents.google.com/patent/CN101487482A/en?oq=CN101487482

China Patent: http://epub.cnipa.gov.cn/

Abstract

The invention provides a force changeable, cyclic and reversible angular motion gas spring. A cylinder body and a rear sealing pressure regulating system are weld together to form an enclosed gas spring cylinder body, an O-shaped ring and a directional floating piston are combined with a positioning convex groove of the cylinder body to generate friction force for an angular shaft under the action of power source nitrogen gas, meanwhile, the volume of a gas chamber is changed by the rear sealing pressure regulating system to change the value of the friction force, thus realizing cyclic and reversible motion and angular motion. The rotation friction force of the novel gas spring is changeable and adjustable, and an adjustment angle is cyclic and reversible, which can realize unlimited adjustment of a cyclic angle and can realize fixed value adjustment of the cyclic angle, and meets requirements of a certain emerging and specific products and industries.

Description

A kind of gas spring with variable force value and circulating and reversible rotation angle

Technical field

The present invention relates to a kind of air spring, particularly a kind of gas spring with variable force value and circulating and reversible rotation angle.

Background technique

The pattern of air spring motion in the past is the single pressure stretch motion of contracting, and the air spring of the type is owing to function singleness, application is limited, can not satisfy for example medical apparatus angle adjustment especially, computer monitor, TV-set carriage angle adjustment or the like some emerging certain products and industries.

Summary of the invention

The invention provides a kind of gas spring with variable force value and circulating and reversible rotation angle.

In order to solve above technical problem, a kind of gas spring with variable force value and circulating and reversible rotation angle of the present invention, forming built-in directed floating piston in smooth rotation output unit, cylinder body, the cylinder body, power source and back envelope voltage-regulating system by the advancing slip pearl in corner axle and the cylinder body forms, described cylinder body welds together with back envelope voltage-regulating system forms airtight air spring cylinder body, described directed floating piston in the air spring cylinder body, is the power source region with O type ring seal device between described directed floating piston and back envelope voltage-regulating system.

Described corner shaft rear end can be that cone also can be the plane.

When described corner shaft rear end is the plane, the corner positioning bead is installed on this plane.

Described directed floating piston front can be that taper hole also can be the plane.

When described directed floating piston front was the plane, a basic circle had been established many equal angles in this upper edge, plane, symmetrical pit.

The advantage of above structure is: this gas spring with variable force value and circulating and reversible rotation angle welds together with back envelope voltage-regulating system by cylinder body forms airtight air spring cylinder body, O type circle and directed floating piston, in conjunction with the location tongue of cylinder body under the effect of power source nitrogen, the corner axle is produced frictional force, and change the size of frictional force simultaneously by the volume of back envelope regulating system change air cavity.Realize that like this circulating and reversible rotates, the corner motion, and this novel air spring rotation friction variable adjustable, and the angle modulation circulating and reversible.Can realize that not only cycle perspective is infinitely adjustable, can also realize that the cycle perspective definite value is adjustable.Its appearance will have been satisfied some emerging certain products and industries.It can be widely used in some occasion work light illumination direction adjusting etc.

Description of drawings

Fig. 1 is the structural representation of the embodiment of the invention 1;

Fig. 2 is the structural representation of the embodiment of the invention 2.

Embodiment

Specific embodiment 1:

As shown in Figure 1, the rear end of corner axle 1 is a cone, form smooth rotation output with advancing slip pearl 3, cylinder body 2 welds together with back envelope voltage-regulating system 7 forms airtight air spring cylinder body, there is the directed floating piston 5 of taper hole O type circle 4 and front, under the effect of power source nitrogen 6, the awl end of corner axle 1 is produced frictional force in conjunction with the location tongue of cylinder body 2, back envelope regulating system 7 is the sizes that change frictional force by the volume that changes air cavity.Selecting corner axle 1 and directed floating piston 5 to be the tapered sleeve friction type in Fig. 1, is in order to strengthen the effect of frictional engagement face stable center.It is applicable on the apparatus of any change angle.

Specific embodiment 2:

As shown in Figure 2, corner axle 1 is formed smooth rotation output with advancing slip pearl 3, different is with corner axle among Fig. 11, corner axle 1 rear end is not that cone is the plane among Fig. 2, corner positioning bead 8 is just installed on this plane, cylinder body 2 welds together with back envelope voltage-regulating system 7 forms airtight air spring cylinder body, O type circle 4 is contained on the directed floating piston 5, different is that directed floating piston 5 fronts have been not taper holes, be the plane and processed many equal angles along certain circle, the symmetry pit, in conjunction with the location tongue of cylinder body 2 under the effect of power source nitrogen 6, corner axle 1 ear end face is implemented thrust, and corner positioning bead 8 at this moment just should drop on the front-end face of directed floating piston 5 in the symmetrical grooves, and corner power size is born object gravity+outer active force.Back envelope regulating system 7 is the sizes that change thrust or corner power by the volume that changes air cavity.It is applicable to the air spring of this circulating and reversible angle of Fig. 2 definite value adjustable structure on the apparatus of definite value angle modulation.

Claims (5)

Hide Dependent

- gas spring with variable force value and circulating and reversible rotation angle, form built-in directed floating piston in smooth rotation output unit, cylinder body, the cylinder body, power source and back envelope voltage-regulating system by the advancing slip pearl in corner axle and the cylinder body and form, it is characterized in that: described cylinder body welds together with back envelope voltage-regulating system forms airtight air spring cylinder body; Described directed floating piston in the air spring cylinder body, is provided with the power source region with O type ring seal device between described directed floating piston and back envelope voltage-regulating system.

- a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 1 is characterized in that: described corner shaft rear end can be that cone also can be the plane.

- a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 2 is characterized in that: when described corner shaft rear end is the plane, the corner positioning bead is installed on this plane.

- a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 1 is characterized in that: described directed floating piston front can be that taper hole also can be the plane.

- a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 4 is characterized in that: when described directed floating piston front was the plane, a basic circle had been established many equal angles in this upper edge, plane, symmetrical pit.

Claims (5) patent gas spring with variable force value and circulating and reversible rotation angle

1. gas spring with variable force value and circulating and reversible rotation angle, form built-in directed floating piston in smooth rotation output unit, cylinder body, the cylinder body, power source and back envelope voltage-regulating system by the advancing slip pearl in corner axle and the cylinder body and form, it is characterized in that: described cylinder body welds together with back envelope voltage-regulating system forms airtight air spring cylinder body; Described directed floating piston in the air spring cylinder body, is provided with the power source region with O type ring seal device between described directed floating piston and back envelope voltage-regulating system.

2. a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 1 is characterized in that: described corner shaft rear end can be that cone also can be the plane.

3. a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 2 is characterized in that: when described corner shaft rear end is the plane, the corner positioning bead is installed on this plane.

4. a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 1 is characterized in that: described directed floating piston front can be that taper hole also can be the plane.

5. a kind of gas spring with variable force value and circulating and reversible rotation angle according to claim 4 is characterized in that: when described directed floating piston front was the plane, a basic circle had been established many equal angles in this upper edge, plane, symmetrical pit.

Gas spring capable of adjusting relief pressure

Patent No.:CN201202761 Date:2008-01-14

Google Patent: https://patents.google.com/patent/CN201202761Y/en?oq=CN201202761

China Patent: http://epub.cnipa.gov.cn/

Abstract

The utility model provides an adjustable pressure relief gas spring which is composed of a gas spring cylinder body, a piston and a piston rod riveted with the piston; the cylinder body is welded with a back seal together to construct an airtight gas spring cylinder body; a pressure relief hole and a work position used for mounting the pressure relief part are arranged on the back seal; a seal piece is mounted on the bottom part of the back seal pressure relief work position; a gasket is pressed on the seal piece. The gas spring which adopts the structure to realize the pressure relief adjustment through adjusting the pressure relief screw outwards after the pneumatic is once mounted; thereby, the best application effect is realized through adjustment after the pneumatic is once mounted; the assembly and disassembly of the gas spring are convenient.

Description

A kind of can regulate is rushed down push-type gas spring

Technical field

The utility model relates to a kind of air spring, and particularly a kind of can regulate is rushed down push-type gas spring.

Background technique

The perfection of air spring performance, the increase of function is to change along with client’s demands of applications.Sometimes air spring is on some product or apparatus, the installing/dismounting inconvenience, do not have a kind of can be once good and sound after again through adjusting the air spring that just can reach best using effect.

The model utility content

The utility model provides a kind of can regulate to rush down push-type gas spring.

In order to solve above technical problem, a kind of can regulate of the present utility model is rushed down push-type gas spring, reaching the piston rod of riveting with piston by air spring cylinder body, piston forms, described cylinder body is connected together with back soldering and sealing and forms airtight air spring cylinder body, after seal up to rush down and press the hole and the station that rushes down pressure part is installed, Sealing is contained in the back envelope and rushes down the bottom of pressing station, and pad is pressed on the Sealing.

Described pad seals riveting with the back, rushes down and press the screw front end to be the needle shape, and two small blind holes are anyhow arranged.

Described by pad, seal ring, rush down press that screw forms rush down pressure part can after seal up horizontal assembling, also can vertically assemble at the ear end face that the back is sealed.

The advantage of the above structure of the utility model is: adopt air spring on some product or apparatus, sometimes installing/dismounting inconvenience, for make air spring in use can be once good and sound after again through adjusting the using effect that just can reach the best, the utility model is taked to be connected together in air spring cylinder body and back soldering and sealing and is formed airtight air spring cylinder body, after seal up to rush down and press the hole and the station that rushes down pressure part is installed, Sealing is contained in the back envelope and rushes down the bottom of pressing station, pad is pressed in the structure on the Sealing, and make bearing pressure F1 or pressure F3 15-25% greater than normal use value, press the screw realization adjustable by slowly outwards regulating to rush down, thereby reach once good and sound again through adjusting the using effect that just can reach best.

Description of drawings

Figure is a structural representation of the present utility model.

Embodiment

As shown in the figure, Sealing 6 is installed on the piston 1, piston 1 and piston rod 2 are riveted together, between piston rod 2 and cylinder body 3, be provided with sealing guidance system 9, and cylinder body 3 welds together with back envelope 4 and form airtight air spring cylinder body, be processed with on the back envelope 4 to rush down and press the hole and the station that rushes down pressure part is installed, Sealing 7 is contained in back envelope 4 and rushes down the bottom of pressing station, pad 5 is pressed on the Sealing 7, and with back envelope 4 rivetings, rush down and press screw 8 front ends to be the needle shape, and two small blind holes are anyhow arranged.

When air spring rushes down the realization of pressing performance, the bearing pressure F1 of product or pressure F3 should be greater than the 15-25% of normal use value, slowly outwards regulate to rush down after installing and press screw 8, the sealing center line that little cross-drilled hole withdraws from Sealing 7 on the needle shape just begins to rush down pressure, inwardly regulate to rush down rapidly when rushing down and press screw 8, it is closed rush down pressure to suitable power value.

The above-described this laminated structure that rushes down is not limited only to laterally assembling on back envelope 4, also can vertically assemble at the ear end face of back envelope 4.

Claims (3) – patented gas spring capable of adjusting relief pressure

1, a kind of can regulate is rushed down push-type gas spring, reaching the piston rod of riveting with piston by air spring cylinder body, piston forms, it is characterized in that: described cylinder body is connected together with back soldering and sealing and forms airtight air spring cylinder body, after seal up to rush down and press the hole and the station that rushes down pressure part is installed, Sealing is contained in the back envelope and rushes down the bottom of pressing station, and pad is pressed on the Sealing.

2, a kind of can regulate according to claim 1 is rushed down push-type gas spring, it is characterized in that: described pad seals riveting with the back, rushes down and press the screw front end to be the needle shape, and two small blind holes are anyhow arranged.

3, a kind of can regulate according to claim 1 is rushed down push-type gas spring, it is characterized in that: described by pad, seal ring, rush down press that screw forms rush down pressure part can after seal up horizontal assembling, also can vertically assemble at the ear end face that the back is sealed.

Three-segment strength gas spring with pressure discharging function

Patent No.:CN201166080Y Date:2008-01-14

Google Patent: https://patents.google.com/patent/CN201166080Y/en?oq=CN201166080

China Patent: http://epub.cnipa.gov.cn/

Abstract

The utility model provides a three-section force spring with pressure unloading function, which comprises a cylinder body, a piston and a damping oil region which are arranged inside the cylinder body, a piston rod connected with the piston and a rear block; a supporting gasket is arranged on the lower part of the piston; a valve plate is glidingly fixed between the piston and the supporting gasket; and the supporting gasket and the valve plate are supported by four-point contact to form a one way valve type piston. The structure adopts the one way valve type piston formed by the special valve plate; and a section of a damping reduction groove, which is a pressure reduction groove, is processed on the cylinder wall of the gas spring to achieve the effect of pressure unloading. The appearance of the three-section force spring meets the application requirements of certain body-building apparatus and medical equipment.

Description

A kind of have three sections strength springs of the compression functions of rushing down

Technical field

The utility model relates to a kind of air spring, and particularly a kind of have three sections strength springs of the compression functions of rushing down.

Background technique

The applicable field of air spring is more and more wider, and it is also more and more diversified to the attainable performance of air spring when using, and existing at present air spring is when doing olefiant gas mixing working pressure, it can only present two sections two kinds of power: the one, and this gas section is light power, the 2nd, the damping force that the oil section produces is a gravity.Can on some apparatus, it not need very long damping, but it to use light power on the contrary after damping one segment length, bad even can not use in a lot of fields using effect.

The model utility content

The utility model provides a kind of and can produce three sections power and have the air spring that rushes down compression functions.

In order to solve above technical problem, a kind of three sections strength springs of the compression functions of rushing down that have of the present utility model, comprise that the piston in cylinder body, the cylinder body blocks up with damping oil district, the piston rod that is connected with piston, back, described support pad is located at the piston below, valve block slides and is fixed between piston and the support pad, support pad is at 4 with valve block and contacts support, constitutes the one-way valve type piston.

Described piston has a plurality of straight hole forms and is pressed with horizontal damping slot.

Described on cylinder barrel the inboard outwards be provided with and fall damping slot.

The advantage of above structure is: shown in Figure 2, described these three sections strength springs present three power sections of jump type in the overall process of moving and also can be described as three kinds of power values, and the one, this gas section is light power, the 2nd, cloudy Buddhist nun’s power that the oil section produces, the 3rd, gravity.Can on some apparatus, it not need very long damping, but it to use light power on the contrary after damping one segment length.Therefore, the one-way valve type piston that has adopted special valve block to form, and having processed one section on the air spring casing wall, to fall damping slot be relief groove, makes it play the effect of rushing down pressure.Some physical fitness apparatus and medical device applications demand have been satisfied in its appearance.

Description of drawings

Fig. 1 is a structural representation of the present utility model;

Fig. 2 is the force value tests plotted curve of three sections power;

Fig. 3 is the enlarged view of piston in the utility model;

Fig. 4 is the enlarged view of support plate in the utility model.

Embodiment

As shown in Figure 1, back stifled 1 welds together with cylinder barrel and has just formed the airtight cylinder body of air spring.Piston 4 is built in the cylinder body, and seals with pilot seal system 8 between the cylinder body.Piston rod 2 is to be sealedly and fixedly connected together by O type circle 3 with piston assembly.As shown in Figure 3, described piston 4 adopts a plurality of straight hole forms and is pressed with horizontal damping slot 9, and support pad 5 is located at piston 4 belows, and valve block 6 slides and is fixed between piston 4 and the support pad 5, and slides between piston 4 and support pad 5; As shown in Figure 4, support pad 5 has 4 convex-concave points 10, and support pad 5 is at 4 with valve block 6 and contacts support, and what guarantee that valve block 6 is opened spacingly guarantees valve block 6 flexibility when closing again; As mentioned above, piston 4, valve block 6, support pad 5 constitute the one-way valve type piston.Valve block 6 is just to have constituted one-way valve when air spring stretches or compress, and reason is that damping hole and the groove on the piston blocked sealing by valve block when air spring compresses, and just opens when air spring stretches.Fall damping slot 7 and be on cylinder barrel outwards inboard, the depth of groove be according to fall resistance what, fall the resistance zone and decide.Valve block had been closed part piston hole or groove when its effect was exactly the air spring lower compression, was moveable to rush down in it has formed when falling damping slot to have reached the effect of falling resistance, step-down, realized user’s purpose.

Claims (3)

Hide Dependent

1, a kind of have three sections strength springs of the compression functions of rushing down, comprise that the piston in cylinder body, the cylinder body blocks up with damping oil district, the piston rod that is connected with piston, back, it is characterized in that: described support pad is located at the piston below, valve block slides and is fixed between piston and the support pad, support pad is at 4 with valve block and contacts support, constitutes the one-way valve type piston.

2, a kind of three sections strength springs of the compression functions of rushing down that have according to claim 1, it is characterized in that: described piston has a plurality of straight hole forms and is pressed with horizontal damping slot.

3, a kind of three sections strength springs of the compression functions of rushing down that have according to claim 1 is characterized in that: described on cylinder barrel the inboard outwards be provided with and fall damping slot.

Claims (3) of Three-segment gas spring patent

1, a kind of have three sections strength springs of the compression functions of rushing down, comprise that the piston in cylinder body, the cylinder body blocks up with damping oil district, the piston rod that is connected with piston, back, it is characterized in that: described support pad is located at the piston below, valve block slides and is fixed between piston and the support pad, support pad is at 4 with valve block and contacts support, constitutes the one-way valve type piston.

2, a kind of three sections strength springs of the compression functions of rushing down that have according to claim 1, it is characterized in that: described piston has a plurality of straight hole forms and is pressed with horizontal damping slot.

3, a kind of three sections strength springs of the compression functions of rushing down that have according to claim 1 is characterized in that: described on cylinder barrel the inboard outwards be provided with and fall damping slot.

Stroke connection size constant pressure adjustable gas spring

Patent No.:CN201166080Y Date:2008-01-14

Google Patent: https://patents.google.com/patent/CN201166080Y/en?oq=CN201166080

China Patent: http://epub.cnipa.gov.cn/

Abstract

The utility model provides a pneumatic spring for connecting strokes, having constant size and adjustment pressure, whose pressure adjusting screw sleeve and pressure adjusting piston system are locked by a connecting clip spring, wherein the pressure adjusting screw sleeve is provided with a guide screw and is provided in a special guide slot of back seal in a sliding type, a pressure adjusting screw rod is provided at the inner side of the back seal, the front of the pressure adjusting screw rod is screwed into the internal screw of the pressure adjusting screw sleeve, the pressure adjusting screw rod is clipped by the clip spring at the outer side of the back seal, a pressure adjusting hand wheel is provided on the pressure adjusting screw rod and is screwed and pressed firmly by a connecting fixing screw. The utility model is suitable for large equipments and can be designed according to the stroke and the allowance maximum size of the installment position, the length of the pressure adjusting space is 1/2 or more of the stroke.

Description

The constant adjustable in pressure air spring of a kind of stroke Conncetion cimension

Technical field

The utility model relates to a kind of air spring, the constant adjustable in pressure air spring of particularly a kind of stroke Conncetion cimension.

Background technique

Existing a kind of its deficiency of pressure regulation air spring is on the market: 1. can only do the trace adjustment of F1 bearing pressure when low, and be can only raise on former power value basis; 2. it has changed the original stroke of air spring when adjusting.

The model utility content

The utility model provides a kind of stroke Conncetion cimension constant adjustable in pressure air spring.

In order to solve above technical problem, the constant adjustable in pressure air spring of a kind of stroke Conncetion cimension of the present utility model, be connected together and form complete air spring cylinder body by cylinder body and back soldering and sealing, built-in piston and relief piston system in described air spring cylinder body, described piston is connected with fixed piston rod by O type circle and pilot seal system, described relief piston system is connected with the pressure regulation screw mandrel, described pressure regulation silk braid locks by being connected jump ring with the relief piston system, on the pressure regulation silk braid, pacify guide screw, the pressure regulation silk braid is slidably mounted in the specific guiding groove of back envelope, the inside front cover side is debug the silk pressing bar in the back, described pressure regulation screw mandrel front screws in the internal thread of pressure regulation silk braid, the pressure regulation screw mandrel is blocked by jump ring in the envelope outside, back, and the pressure regulation handwheel is positioned on the pressure regulation screw mandrel, is screwed by the connection fastening screw to fasten.

Described relief piston system is made up of back air cavity Sealing and piston seal.

But described relief piston system is positioned at 1/2 pressure regulation travel position the best.

The advantage of above structure is: the utility model is at relatively using on the main equipment, as the mold open of injection machine, and the demoulding discharging of stretcher etc.This air spring can design according to the overall dimensions that required stroke and mounting point allow, the pressure regulation space length to guarantee running length 1/2 or longer.

Description of drawings

Figure is a structural representation of the present utility model.

Embodiment

As shown in the figure, piston rod 4 is built in the cylinder body 5, and with 1 sealing of pilot seal system, piston 2 mounting means O type circles 3, piston rod 4 is to be riveted together with piston 2, cylinder body 5 welds together with back envelope 12 forms complete air spring cylinder body, relief piston system 6 is become one by back air cavity Sealing and piston, pressure regulation silk braid 8 and relief piston system are fitted together, by connecting jump ring 7 lockings, guide screw 9 is positioned on the pressure regulation silk braid 8, adjusts length pressure regulation silk braid 8 can be slided in the specific guiding groove of back envelope 12, pressure regulation screw mandrel 10 is contained in envelope 12 inboards, back, the front screws in the internal thread of pressure regulation silk braid 8, and pressure regulation screw mandrel 10 is blocked by jump ring 13 in envelope 12 outsides, back, and only rotating not can axial motion, pressure regulation handwheel 11 is positioned on the pressure regulation screw mandrel 10, is screwed by connection fastening screw 14 to fasten.Pressure regulation of the present utility model is exactly the size that changes the volume of air cavity, carries out the compression and the amplification of volume on the strong basis of the inflatable chamber level pressure of original per unit volume, has effectively changed the size of internal pressure.But the optimum state of the inflatable chamber of original per unit volume is positioned at 1/2 pressure regulation travel position for well with relief piston system 6, and the internal pressure size is adjusted equal scope is arranged on this position, also can set the highest as required or nil-norm is determined.

Claims (3) of pressure adjustable gas spring patent

1. constant adjustable in pressure gas spring of stroke Conncetion cimension, be connected together and form complete air spring cylinder body by cylinder body and back soldering and sealing, built-in piston and relief piston system in described air spring cylinder body, described piston is connected with fixed piston rod by O type circle and pilot seal system, described relief piston system is connected with the pressure regulation screw mandrel, it is characterized in that: described pressure regulation silk braid locks by being connected jump ring with the relief piston system, on the pressure regulation silk braid, pacify guide screw, the pressure regulation silk braid is slidably mounted in the specific guiding groove of back envelope, the inside front cover side is debug the silk pressing bar in the back, described pressure regulation screw mandrel front screws in the internal thread of pressure regulation silk braid, the pressure regulation screw mandrel is blocked by jump ring in the envelope outside, back, the pressure regulation handwheel is positioned on the pressure regulation screw mandrel, is screwed by the connection fastening screw to fasten.

2. the constant adjustable in pressure air spring of a kind of stroke Conncetion cimension according to claim 1 is characterized in that: the relief piston system is made up of back air cavity Sealing and piston seal.

3. the constant adjustable pressure gas spring of a kind of stroke Conncetion cimension according to claim 1 is characterized in that: but the relief piston system is positioned at 1/2 pressure regulation travel position the best.